3D printing is becoming more widely available, enabling the creatives of the industry to enter into a whole new world of manufacturing.

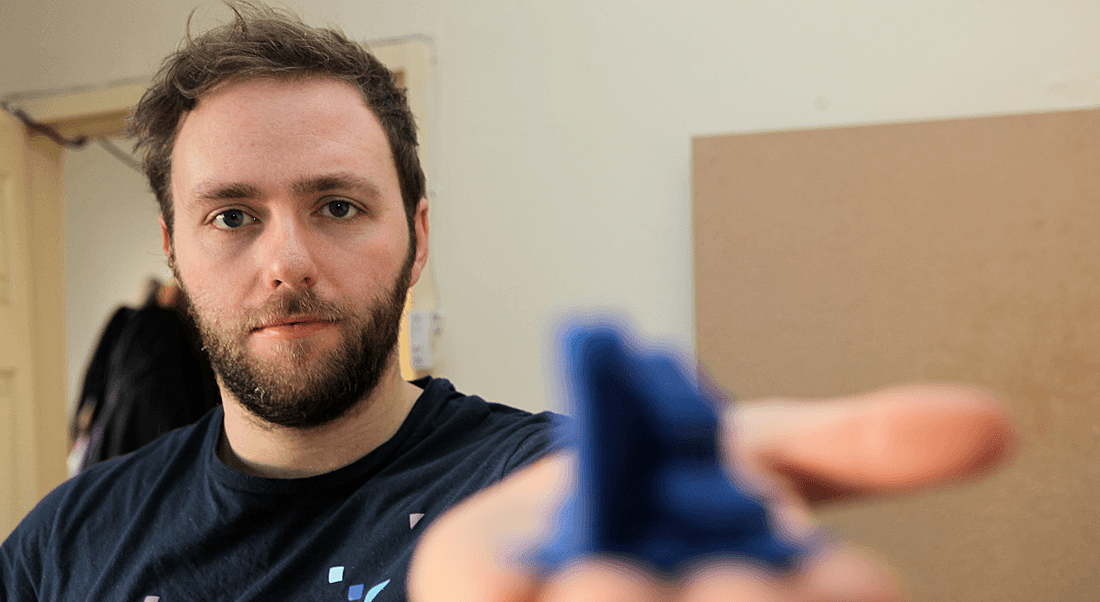

3D printing is not just for college projects and professional manufacturers anymore. For 3D designers like Jamie Tully, the work is getting much more varied and creative.

Tully spoke to us about what his job entails, how the 3D design industry is changing and how he stays on top of everything.

What is your role within this company?

Sole operator, design/printing/maintenance.

If there is such a thing, can you describe a typical day in the job?

A typical day for me involves receiving orders, usually in the form of 3D models from customers, and then we’ll usually discuss suitable materials for the print and/or possible design changes where a model might not be suitable for printing. After that, I’ll set up the printer to print and let it run, while monitoring it to make sure it’s printing well, and adjust where required.

What types of project do you work on?

Mostly student college projects and prototyping with some maker, art and hobby projects too.

What skills do you use on a daily basis?

Problem solving, 3D modelling/design, programming and electronics, customer communication and online marketing.

What is the hardest part of your working day?

While 3D printing is a very flexible manufacturing process, not everything is suitable and every job is unique. Some designs I get can be quite difficult and time-consuming to find a solution for, and to get the best quality print. However, they all add to my experience and over time, I find I can figure them out much quicker.

Do you have any productivity tips that help you through the working day?

Getting a good start. I work from home, I take my time on breakfast – probably too long – but I get a good bit of the mindless news catch-up and web trawling out of the way to lessen distraction throughout the day. Apart from that, a good continuous music playlist that I don’t have the urge to keep flicking through.

When you first started this job, what were you most surprised to learn was important in the role?

Putting myself out of my comfort zone. There were many jobs I took at the start that I didn’t think I could do, but I forced myself to accept and figure them out and I’ve yet to fail to deliver. Customer communication is a biggie too. I find having a good relationship with the customer makes the job go much smoother and helps keeps things on track in cases where difficulties or delays occur.

How has this role changed as this sector has grown and evolved?

It’s getting busier as people become more aware of the service and its quality and affordability. I’ve also been doing a lot more 3D modelling and design, especially for makers and hobbyists who are using the service for their own projects and require bespoke parts.

What do you enjoy most about the job?

I have great customers, all with a strong interest in the projects they are working on. [They] are always quick to respond when I’m asking for more information from them, to help me decide on the best options for their print.

Looking for jobs in tech or science? Check out our Employer Profiles for information on companies hiring right now.